Overview: This research project combines structural failure analysis, finite element analysis, reliability methods, and quality control concepts to develop a methodology for the reliability assessment of railroad wheels. Failure analysis focuses on strength and fatigue crack growth methods to model the rim shattering and cracking failure modes, and implements these methods with finite element stress analysis. Structural analysis is combined with limit state-based reliability analysis methods and prior inspection, testing, and failure data, to develop failure probability estimates of railroad wheels. The next step is to use these results to develop an inspection planning methodology for reliability assessment of wheels currently in use, based on acceptance sampling concepts. The emphasis is on minimizing the number of wheels inspected, while at the same time developing high confidence in the reliability assessment.

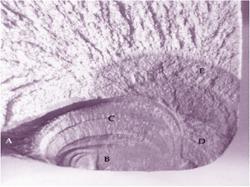

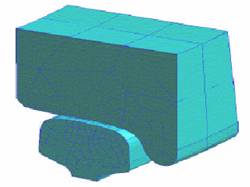

Example Applications: Several failure modes have been observed in railroad wheels, such as shattered rim, vertical split rim, thermal cracking etc. (Fig. 1 and Fig. 2). Shattered rims are the result of large fatigue cracks that propagate roughly parallel to the wheel tread surface. Vertical split rims are the result of cracks that propagate vertical to the wheel tread surface. Thermal cracking refers to small cracks on the tread surface or loss of small pieces of tread material (spalling). This study includes accurate modeling of the different failure modes in the proposed methodology (Fig. 3).

|

|

|

|

Fig. 1 Fracture of the Wheel

|

Fig. 2 Crack Growth Pattern

|

Fig. 3 Finite Element Modeling of the

Wheel-rail contact |

Potential Applications: Fatigue failure is one of the most common failure modes in engineering materials. The proposed probabilistic fatigue analysis methodology can be applied to other structural and mechanical components. The efficient reliability estimation and inspection planning methods being developed in this project are applicable to a wide range of problems across many engineering disciplines.