Our structural health monitoring (SHM) research is developing techniques for:

- Detection, localization, and quantification of structural damage (damage diagnosis)

- Forecasting future damage growth and estimation of the remaining useful life of the structure (prognosis)

- Uncertainty quantification in damage diagnosis

- Uncertainty propagation to perform probabilistic system prognosis.

NDE Techniques

Multiple non-destructive evaluation (NDE) techniques are being studied for damage detection and localization in heterogeneous materials

- Infrared Thermography

- Digital Image Correlation (DIC)

- Vibration-based techniques

- Harmonic vibration testing

- Non-impact resonance acoustic spectroscopy (NIRAS)

- Vibro-acoustic modulation (VAM)

| Watch video on VAM here: |

Modeling Techniques

Physics-based Models

- Finite element modeling

- Nonlinear wave propagation in concrete slabs containing hidden cracks

- Piezoelectric transducer actuated Lamb wave propagation in thin metallic components

- Heat conduction in concrete slabs containing hidden cracks

- Thermal modeling of exothermic composite curing reaction

Machine Learning Models

Machine learning techniques are utilized for feature automation and interior damage diagnosis methodology.

- Feed-forward neural networks

- Convolutional neural networks

- Transfer learning

Damage Diagnosis

- Detection

- Based on higher singular vectors (Harmonic vibration testing)

- Based on resonance frequency shift (NIRAS)

- Based on presence of sidebands in linear spectral response (VAM)

- Based on thermal image processing (Thermography)

- Localization / estimation

- Deviation from sinusoid (Harmonic vibration testing)

- Strength of sideband sum (VAM)

- Thermal image processing (Thermography)

Damage Prognosis

- Subcritical fatigue crack propagation using linear elastic fracture mechanics

- Estimation of crack growth model parameters using laboratory test data

Uncertainty Quantification in Diagnosis and Prognosis

- Global sensitivity analysis

- Bayesian updating

- Markov Chain Monte Carlo

- Monte Carlo dropout

- Diagnosis uncertainty

- Global sensitivity analysis

- Monte Carlo sampling

- Model error calibration

Applications

Concrete Structural Health Monitoring

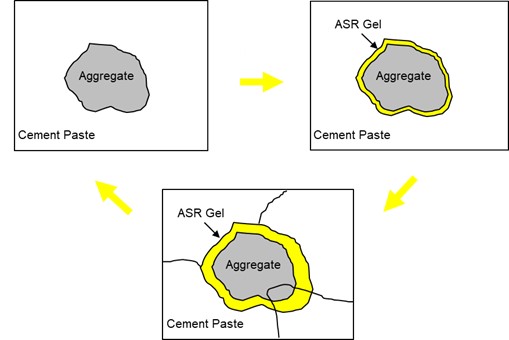

NDE Techniques are being studied to detect and localize damage due to alkali-silica reaction (ASR) in concrete specimens.

- ASR is a chemical reaction between highly alkaline cement paste and reactive aggregates in cement, produced over time.

- In the presence of moisture, ASR gel expands, producing cracks in the specimens.

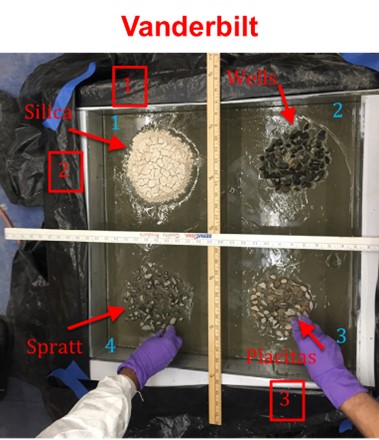

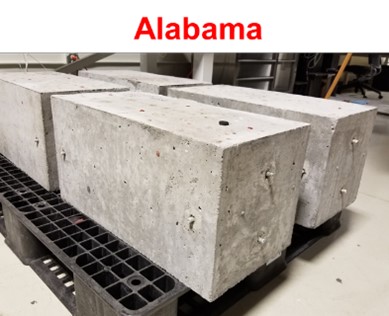

Concrete Experimental Specimens

Plain Concrete

- Vanderbilt - 1 - 2’x2’x6”

- Alabama - 4 - 2’x1’x1’

Reinforced Concrete

- Nebraska - 4 – 2’x1’x1’

Concrete Damage Diagnosis Techniques

- Vibro-acoustic modulation (VAM): Modulation of a higher excitation frequency by a lower excitation frequency caused by delamination or cracks in structural components, resulting in the appearance of sidebands in the linear spectral response. The sidebands are used to both detect and localize the damage.

- Harmonic Testing: Innovative damage-sensitive features for damage detection based on higher singular vectors. Deviation from sinusoid used to localize damage.

- Machine Learning: Training of machine learning models using finite element simulations. Both prediction and classification models are constructed, and used for damage localization with actual physical specimens.

Real-Time Cure Monitoring of Fiber-reinforced Polymer Composites using Infrared Thermography

Higher cost and longer manufacturing lead times associated with FRP composites hinder their utilization in high-volume industries (wind, consumer automotive, and compressed gas storage). Real-time monitoring of the curing process can be crucial for adaptive decision-making to reduce cycle time, energy usage, and timely potential flaw identification and repair.

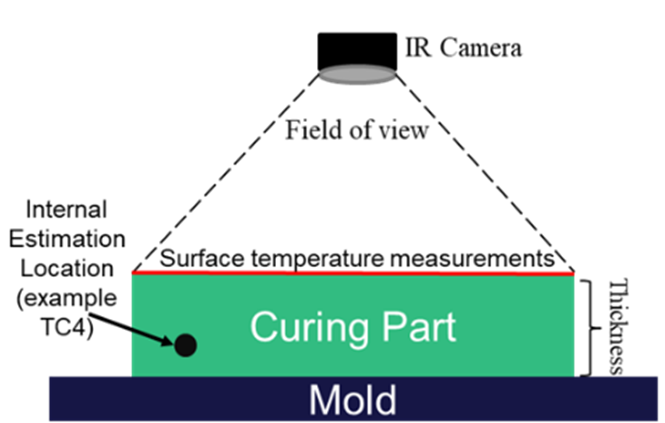

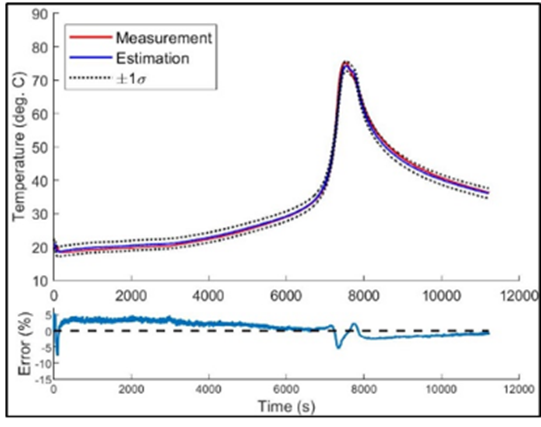

We developed a methodology utilizing heat conduction and cure kinetics models, surface temperature measurements from thermography, and a Kalman filter to successfully perform real-time cure monitoring.  The methodology is applied to monitor key process variables in an FRP composite part manufactured at the National Renewable Energy Lab (NREL) Composites Manufacturing Education and Technology (CoMET) facility.

The methodology is applied to monitor key process variables in an FRP composite part manufactured at the National Renewable Energy Lab (NREL) Composites Manufacturing Education and Technology (CoMET) facility.

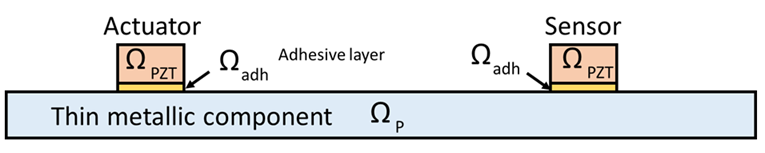

Bayesian information fusion for crack size diagnosis in thin plate structures

Ultrasonic guided waves are commonly used for monitoring fatigue-induced crack growth in thin metallic structures. We developed a methodology for fusing information from multiple actuator-sensor paths to compensate for environmental effects on a sensed signal, and to estimate crack size under varying environmental conditions.

- Guided waves actuated and sensed using piezoelectric transducers

- Changes in the sensed signal characteristics, as captured by the change in the damage index, and analyzed to estimate the crack size.

- Damage index defined based on short-time Fourier transform

- Computational modeling of the governing physics

- Sensitivity analysis, dimension reduction and surrogate modeling

- Bayesian technique to fuse information obtained from multiple actuator-sensor paths

Funding

Current People

- Sankaran Mahadevan, Professor

- Douglas Adams, Professor

- Pranav Karve, Assistant Research Professor

- Yanqing Bao, Postdoctoral Research Scholar

- Sarah Miele, Ph.D. Student

- Yulin Guo, Ph.D. Student

- Gbandi Nikabou, Ph.D. Student

- Christopher Nash

- Julia Finfrock, Undergraduate Researcher

- David Koester, Research Engineer

- Garrett Thorne, Staff Engineer

Publications

1. Bao, Y., & Mahadevan, S. (2015). Uncertainty quantification of thermal image-based concrete diagnosis. International Journal of Sustainable Materials and Structural Systems, 2(1-2), 77-95.

2. Bao, Y., & Mahadevan, S. (2019). Harmonic vibration testing for damage detection and localization in concrete. Structural Health Monitoring, 18(5-6), 1820-1835.

3. Karve, P., & Mahadevan, S. (2020). On the performance of vibro‐acoustic‐ modulation‐based diagnosis of breathing cracks in thick, elastic slabs. Structural Control and Health Monitoring, 27(3), e2470.

4. Karve, P., Miele, S., Neal, K., Mahadevan, S., Agarwal, V., Giannini, E. R., & Kyslinger, P. (2020). Vibro-acoustic modulation and data fusion for localizing alkali–silica reaction–induced damage in concrete. Structural Health Monitoring, 1475921720905509.

5. Karve, P. M., Guo, Y., Kapusuzoglu, B., Mahadevan, S., & Haile, M. A. (2020). Digital twin approach for damage-tolerant mission planning under uncertainty. Engineering Fracture Mechanics, 225, 106766.

6. Nash, C., Karve, P., Adams, D., Mahadevan, S., & Thorne, G. (2020). Real-time cure monitoring of fiber-reinforced polymer composites using infrared thermography and recursive Bayesian filtering. Composites Part B: Engineering, 198, 108241.